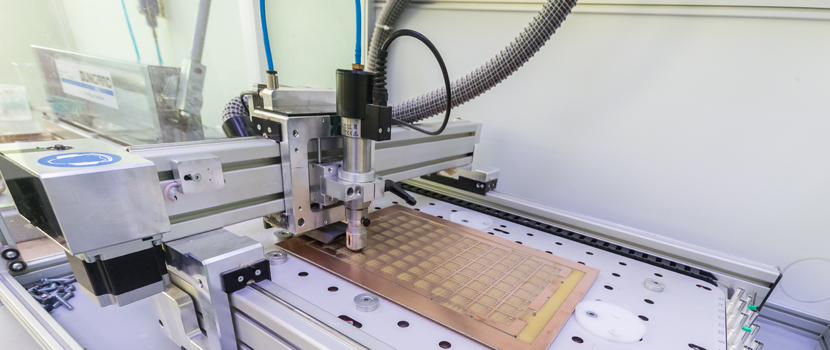

The 20th-anniversary international exhibition of equipment, devices and tools for the metalworking industry "Metalloobrabotka-2019" is coming to an end in Moscow. At the exhibition, SEC of “MSTU "STANKIN" for the first time demonstrated a model of digital manless production and also presented universal CNC systems "AxiOMA Control" and "Perspective" developed by the University. In addition, in the virtual environment provided by our partner VR-Concept, a 3D model of milling and engraving machine developed by a team of students of MSTU "STANKIN" was demonstrated.

This year the University not only traditionally presented its achievements and developments as an exhibitor, but also acted as a co-organizer of the business program. The second day of the 9th international scientific and technical forum "Materials processing technologies, robotics and industry 4.0" was devoted to additive technologies.

Additive technologies in industrial production

A key element of the transition to a new technological order is the development of additive technologies that offer a unified digital approach to the creation of products. Despite the steady growth of the additive technologies market in Russia in recent years, qualitative changes based on domestic developments are needed in this area to intensify development rates. Having considerable experience in the development of additive manufacturing technologies and understanding the challenges facing their development, SEC of “MSTU "STANKIN" initiated the section "Additive technologies in industrial production". The event was held on May 29, 2019, as part of the business program of the “Metalloobrabotka-2019” exhibition and became part of the 9th International scientific and technical forum "Materials processing technologies, robotics and Industry 4.0".

Certain reports on the section were devoted to the problems of 3D printing of plastics, composites, metal alloys and ceramics. In addition to the adaptation and optimization of existing technologies, the leading researcher of SEC of MSTU "STANKIN" Tatiana Tarasova in her report noted the fundamental research in this area and the training of qualified personnel as the main activities of the University.

Technology development is one of the segments of an integrated approach to the development of domestic additive technologies. The development of the powder materials and additive manufacturing equipment industry is necessary for the implementation of qualitative positive changes. JSC "POLEMA", being one of the largest Russian producers of powders, noted the growing demand for domestic powders on the market, as well as the demand for new materials. Head of the research laboratory of JSC "POLEMA" Mikhail Panin said: "POLEMA" has modern equipment that allows solving the most complex problems of the customers. The company produces more than 250 serial brands of powders on Fe, Ni, Co, Сu, Mo, Ti-bases. We have a unique unit for the spheroidization of refractory metals. There are only 7 such units in the world. We produce powders using 5 technologies, some of which are unique in our country. Due to this, we can obtain compositions of powders that cannot be obtained by standard traditional methods. This allows us to ensure the import substitution of all possible types of powders for 3D printing, spraying and surfacing, as well as to combine various powder compositions that allow obtaining finished products with completely unique properties at the output. ”

Domestic 3D printing systems are also developed by efforts of the company "Lasers and equipment", whose industrial installation is now commercially available. The existing rates of development make it possible to predict in the near future the level of accuracy and performance of foreign analogues. During the work of the section, almost all issues important for the development of domestic additive production were raised: the development of technology, materials and equipment. As a result, the participants agreed that a qualitative transition to a new level is possible only with the consolidated development of these three areas.