Cyber-physical systems combine physical and virtual copies of real production facilities, control physical processes and make decentralized decisions. Such systems can self-learn, self-adjust, integrate into one network.

“The digital transformation of industrial enterprises is based on the concepts of Industry 4.0, which rely on technologies such as mathematical modeling, robotics, artificial intelligence, the Internet of Things, cloud computing, predictive analytics and others,” explains Mikhail Klyuev, Ph.D. Associate Professor of the Department of Mechanical Engineering Technology, MSTU STANKIN, - In this case, a cyber-physical system means the creation of a digital analogue of a process that reflects its essence, and the ability to interact with the original. The digital twin within itself has the same components as its physical original. With its help, it is possible to predict the behavior of this or that equipment in different situations with high accuracy ”.

Predicting the behavior of a mechanical device, such as a machine or a drive, makes it possible to move from planned maintenance to so-called predictive maintenance, and allows predicting possible malfunctions. According to the project manager, in the past they tried to predict what would happen to the machine in various situations, but with the advent of digital capabilities, it is possible to predict the behavior of a mechanism based on data on many objects of the same type, which means with a greater degree of accuracy.

“For example, thanks to the measurements collected on the basis of big data, we can predict a voltage surge that is fatal for the drive and calculate the values at which its effect will be moderate,” says Mikhail Klyuev. - In our digital twin, we add those parameters, digital shadows, that we are interested in. These can include geometries, electrical diagrams, thermal models, etc. All these different physical data and models are put together, they can show the state of the twin in various situations necessary to predict the operation of either existing objects, or design new ones. "

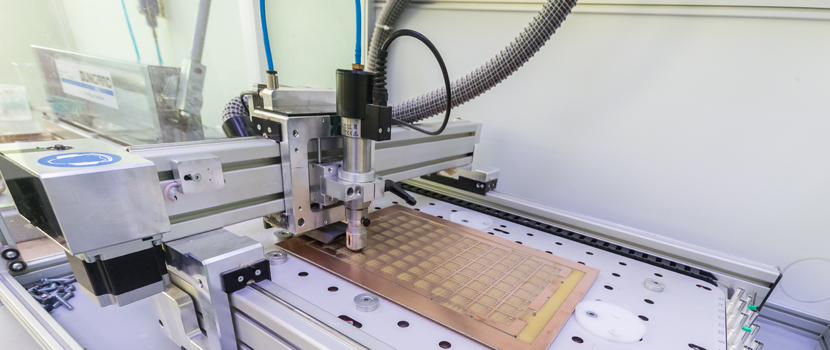

The expert clarifies that the new research is not applied, it is not about a specific drive or model. STANKIN scientists are researching the principles and methods of forecasting that improve the efficiency of equipment. The most important stage is the introduction of computer modeling technologies at the stage of product design. Thanks to digital twins, it is possible to accurately predict the response of equipment to operational loads, and to reduce the operating costs of complex industrial complexes.

The transition from a steam engine to an electric engine led to the fact that the mechanisms used in production became more compact. The use of computing technology has led to automation. With the transition to cyber-physical systems, industrial mechanisms begin to work together, which allows you to get a lot of new information, and thereby improve the technology, and, ultimately, make it cheaper.

MSTU "STANKIN" as a branch university of the machine-tool industry performs the functions of a system integrator and has a full range of scientific, technical, educational and engineering competencies in the formation of the technological base of the machine-building complex of Russia.

Industry in different countries is in the same global competition. Everyone faces the same problems - quality control, wear and tear of consumables, and cheaper production. Research in the field of cyber-physical systems will allow countries that invest in this area to win the competition.